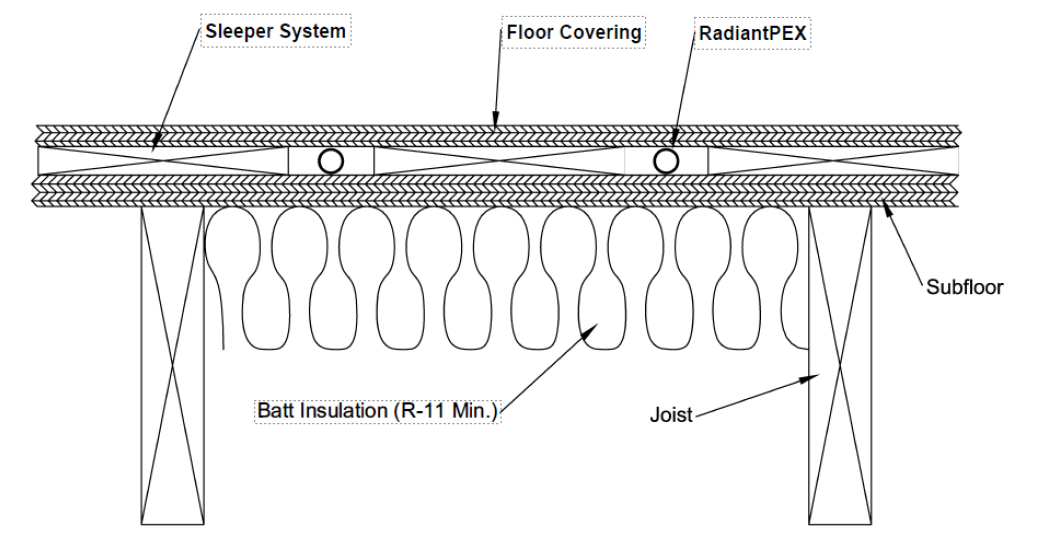

Hydronic floor heating can be installed above the subfloor or slab

in a sleeper system. A sleeper system raises the floor to allow for the

tubing to sit below the floor covering. It may also help conduct the

heat from the tubing into the flooring system. Sleeper systems have

some benefits over other installation methods.

Hydronic floor heating can be installed above the subfloor or slab

in a sleeper system. A sleeper system raises the floor to allow for the

tubing to sit below the floor covering. It may also help conduct the

heat from the tubing into the flooring system. Sleeper systems have

some benefits over other installation methods.

If you have an existing flooring system, i.e. an existing slab or a subfloor where we can not get the tubing below the floor; installing the tubing above the floor in a plywood sleeper system is a great option in adding heat to the zone.

- The sleeper system would be lighter than a new concrete slab to accept the radiant tubing.

- The sleeper system may be the cheapest option compared to a slab or underfloor option.

- Sleeper systems get the tubing up high in the flooring for optimal heat transfer rates than underfloor installations.

- Above floor heating sleeper systems can use some of the lowest water temperatures to heat the space providing higher energy efficiencies.

We classify sleeper systems into two types; site-built and shop-built

Site-built Sleeper Systems are where the installer supplies a wood sleeper; usually 3/4 in. to 1-1/2 in. and then installs the tubing into the channels between the sleepers.

Shop-built Sleepers are factory made panels made for easy installation and maximize heat transfer. They are made to tight tolerances and hold the tubing tighter and improve heat conduction. Installation in usually much faster and cleaner than a site built system.

Site-built Sleeper System

-

Rip plywood sleepers with a gap between them to minimize noise

-

Significantly Reduces Cost (Shop-built panels can be pricey)

-

Maximized flexibility. Not locked into the dimensions of a factory panel

-

More intuitive. Carpenters work in their wheel-house

Shop-built Sleepers

-

Routed factor Panels hold the tubing tight to the channels

-

Quiet -Tight channels limit tubing movement and noise

-

Can be much faster to install due to simplified layout

-

Hight can be minimized due to tighter build tolerances

Types of Shop-built Sleepers

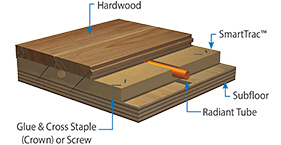

SmartTrac by Watts Radiant

Factory built sleeper system made from 5/8 inch MDF (Medium Density Fiberboard). Accepts 3/8 inch tubing for a low profile. Each board has the straight and return channels so you only have to buy one panel for all applications. Each board is 2 ft. x 2 ft square.

VersaTherm by Legend

Pre-insulated 3/4 inch polypropylene panels are ideal for lightweight installs over subfloors or basement installs where moisture may be an issue. Accepts 1/2 inch tubing and panels click together for fast installations. Finally the entire system is covered by a galvanized steel panel to maximize heat transfer.

Sunboard by NESR

Made from countertop grade fiberboard for stability and moisture resistance. Panels are 5/8 inch thick to accept 3/8 inch tubing. They come 2 ft by 4 ft for easier coverage. Each panel has both straight and return channels cut into them. They are covered with an aluminum conduction layer for maximum heat transfer. Our most affordable solution.

Types of Sleeper System Tubing

Hydronic sleeper system tubing comes in a few different choices and some find it quite confusing. Here is a little details on tubing materials.

PEX

One of the most popular tubing materials for radiant floor heating heating. Low cost, high flexibility, very durable and up to 25 year replacement warranties. However, PEX tubing has a high coefficient of expansion. It grows with temperature! Unless the tubing is tight in the sleepers , it may make noise or rub on fasteners.

PERT

The next generation of plastic slab heating tubing. More flexible than PEX, lower cost, durable and 25 year warranties available. However, PERT tubing has just as high coefficient of expansion as PEX. It grows with temperature! Unless the tubing is tight in the sleepers , it may make noise or rub on fasteners.

PEX-AL-PEX

Has been around for a long time. There is a layer of PEX on the inside of the tubing for corrosion resistance. Surrounded by a layer of aluminum for strength and oxygen barrier. Then a layer of PEX on the outside of the tubing for durability. This is nice tubing to install since the aluminum maintains the tubing shape. I.e. if you bend the tubing it will stay bent. If you straighten the tubing it will stay straight. It does not expand with temperature as PEX and PERT tubing's do so it is an excellent choice where the tubing is not tight in the sleepers to minimize noise and risk of tubing damage.

EPDM

The most flexible tubing we have on the market. The most durable tubing we have on the market, almost unable to be damaged. Very high heat transfer characteristics. No expansion with temperature. Noise free! 25 year warranties available. However, the most expensive tubing we carry. But if you price out a system you may find the EPDM tubing the best for your application.

Conclusion

Above floor heating can speed up heat transfer due to the tubing laying right below the floor covering. They are also lighter than concrete solutions. And since they run at lowered water temperatures the energy savings can pay for the costs over other installation methods.

Get a free estimate to see the options and cost with your heating system.